Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore. Lorem ipsum dolor sit amet, consectetur

The Unipart Way transforms performance and sales.

Fuel efficiency significantly improved for major rail customers

Unipart Consultancy ranked among top management consultants

Chris Dixon appointed Director, Unipart Consultancy

Unipart Consultancy recognised among UK’s leading management consultants by Financial Times

Data-driven energy saving at NHS Supply Chain Maidstone

The problem

This leading train operator needed to know the vehicles and areas of track with the most WSP (Wheel Slip Prevention) events. Without clearly formatted insights, it couldn’t prove the efficacy of a new sanding unit and improve the operation of trains across its network.

The solution

Instrumentel created a monitoring solution that’s capable of keeping tabs on 32 signals continuously. The data is captured and transferred via a Remote Download Module so users can process and analyse the information. Commissioning and testing was carried out alongside the operator’s maintenance team for a smooth installation. And all data is now available from any device with an internet connection.

The Impact

The information now available from Instrumental provides usable insights that allow targeted maintenance of vehicles and track, resulting in:

- Better vehicle reliability

- Improved vehicle availability

- Reduced long-term damage

- Faster maintenance completion

Delivering transport excellence to Selco’s UK branch network

Serck provides specialist design, manufacture, installation, and service of heat transfer technology across a range of sectors and geographies. Their US distribution business focuses on the heavy-duty truck and commercial radiator market.

The radiator market, like many industrial sectors, has been changing at a pace not seen before. Serck expanded its manufacturing and supply capabilities to be able to offer customers an ever-increasing range of products. This led to excess stock and slow-moving products, as well as having the right products in the wrong location which impeded rapid delivery to customers.

Unipart Logistics has a track record of providing a wide range of supply chain services, underpinned by a suite of digital products across multiple sectors and markets.

Not only was this adding excess cost, but it impacted the high levels of customer service that Serck’s customers were used to.

Serck turned to Unipart Logistics for a solution. Unipart Logistics has a track record of providing a wide range of supply chain services, underpinned by a suite of digital products across multiple sectors and markets. Unipart Logistics is widely recognised for its deep-seated expertise in inventory management through long-term logistics partnerships with market-leading customers such as Jaguar Land Rover, Volkswagen, Sky and Vodafone, who rely on Unipart Logistics to take their productivity, quality of service and customer satisfaction to a new level.

The Unipart Logistics team focused on inventory reduction and obsolescence to increase the availability of products. They optimised ERP technology to enable a review of historic sales and demand data, as well as future planning to ensure accurate availability of saleable products. This identified slow-moving and obsolete products and identified products that should not be purchased going forward.

The results were impressive:

- Excess stock reduced by 16%

- Overall sales increased by 23%

- 74% reduction in stock outs

- Lost sales down 42%

Serck managing director Alex Neill said:

“In a successful, mature operation, changes in the marketplace happen very quickly. Having access to data to analyse, predict and manage stock requirements provides a competitive edge in any market.”

“But with the complexities and challenges in the heavy-duty truck and commercial vehicle market, world-class inventory management is essential to any company striving to be the number one choice for our customers in terms of quality, range, service, and delivery. The support we received from Unipart Logistics helped provide technology-driven world class logistics solutions to these challenges. This will underpin our future growth ambitions by aligning our comprehensive market offering to the specific needs of our customers.”

Paradigm Insight helps ScotRail minimise disruption

The problem

ScotRail previously relied on an OTMR (On-Train Monitoring Recorder) for a range of safety and service data. The problem was that ScotRail staff had to manually download the data to perform any kind of analysis – making it hard to work together to solve any issues.

The solution

Instrumentel designed a remote monitoring solution. Data extraction takes place multiple times per second. It’s encrypted and correlated with GPS data for a richer, real-time view of vehicle performance. Instrumentel’s new Diagnostic Hub was also fitted to the fleet in instalments to minimise disruption across the fleet – a testament to Instrumenel’s ‘design for install’ approach.

The Impact

ScotRail now has access to more data than ever before. It’s displayed on Instrumentel’s Paradigm Insight portal, which is available on any device. This means dispersed teams can collaborate to identify key events which might impact passengers, drivers or maintenance teams. The new data is being used as an early warning system for failures as well as for health checks of key assets, such as the engine, battery and brake systems.

UD Enterprise System : designed for agility, built for resilience

Unipart Digital Enterprise System was developed based on Unipart’s extensive experience defining, designing and implementing warehouse management systems for some of the world’s most demanding companies.

When a leading supercar manufacturer approached Unipart to solve a logistics problem, it was clear that no other product could match the flexibility and adaptability that UD Enterprise System could offer in such a fast paced environment.

Compared to volume car manufacturers, supercar production can require far more variation. Every high-performance supercar is customised to an individual car buyer, so the warehouse operation needs to be extremely flexible to ensure the right parts are available at exactly the right time at the production facility.

The supercar manufacturer’s existing system was not optimised for just-in-time delivery of over 180,000 product lines. Much of the operation was still using paper-based systems which yielded low inventory accuracy.

To create a faster, more agile Warehouse Management System it was clear that Enterprise-grade ERP systems weren’t appropriate. They were often too time-consuming to customise, too expensive for implementation in a single site, and too complex to roll out quickly.

However, UD Enterprise System met the requirements perfectly. It’s designed on open source applications with functionality that can be turned on or off. It can be implemented in a matter of weeks and can be customisable to run industrial-scale operations on smaller sites.

UD Enterprise System enables warehouse operators to scan parts at every stage. This data provides new insights – such as the exact time a part was booked into the warehouse – and these can be used to inform decisions at every stage of production.

For the supercar manufacturer, UD Enterprise System delivered specific benefits very quickly. Inventory accuracy jumped to 99.8% and the production facility benefited from just-in-time deliveries enabling smoother, more efficient production.

Moreover UD Enterprise System provided tangible, traceability data, which is imperative when dealing with the high value parts in a supercar.

Proven in the most challenging environment, trusted by the most demanding customers, and transformative in the benefits delivered – that’s UD Enterprise System.

Thinking that goes Beyond Logistics for Jaguar

How we have helped our customer, Jaguar build their competitive advantage in a fast changing world, by finding new ways of improving the service their customers receive.

Our global logistics relationship with Jaguar Land Rover allowed us to monitor their suppliers and their impact on the aftermarket service that Jaguar Land Rover owners were receiving.

The supplier was a major provider of bumpers to the entire UK automotive industry and they were now finding it challenging to meet the aftermarket needs of Jaguar Land Rover, as a result of the increased demand across the industry for new build cars. Resolving this through increasing their capacity, by creating a new factory, would have been a slow and very expensive solution.

Being aware of a potential problem facing both companies, we decided to take full advantage of Unipart’s engineering knowledge and set out to devise an innovative solution.

The idea was for Unipart to take over the responsibility for producing all non-current bumpers for the aftermarket. But rather than doing this within a new and separate factory, we set out to achieve this task entirely within our existing Jaguar parts distribution centre, in order to optimise the handling and stock control of these very bulky items. Drawing upon our Group’s manufacturing skills and expertise, 38 machines were received, installed and commissioned over a two week period, to allow new production to get swiftly underway.

The implementation of this innovative idea had an immediate impact on restoring service levels. It resulted in Jaguar Land Rover customer back orders of 300 different lines being reduced to zero within a month.

This very different solution, which continues today, has also delivered a 30% reduction in bumper inventory and a 50% reduction in storage space for Jaguar Land Rover.

Select another article

Thinking that goes Beyond Logistics for Waterstones

How we have helped our customers build their competitive advantage in a fast changing world, by finding new ways of improving the service their customers receive.

One sector that has clearly witnessed the dramatic consequences of a fast changing world is that of the traditional bookseller. The growth of online sales and electronic media has transformed people’s access to entertainment and information. The historical advantages of the conventional bookshop were now being fast eroded.

In the past, the sector had problems with forecasting, resulting in frequent re-ordering from suppliers and high costs in operational handling, creating long customer fulfilment times of over a week – a rather poor customer experience.

Waterstones needed to rebuild their competitive difference across their 300 shops and this meant finding a new way of speeding up their ability to get stock to stores, while also increasing the number of individual titles in each store. It required a simultaneous reduction in overall stock levels, to allow books to be presented in a new, customer-friendly and visually appealing way.

The Unipart team began by focusing on the key elements of organisational design, cost-to-serve, and supply chain flow. The team made major changes to sales and order processing which significantly increased forecasting accuracy to 98%. This greatly improved relationships with suppliers, thus creating the potential for much greater use of a centralised inventory and the opportunity to significantly drive down costs.

A new 8am next day delivery service was implemented for shops ordering by 4pm the previous day, from the centralised stock holding of 65,000 titles, thus increasing the availability of both new titles and old favourites across the 300 shop estate. This allowed the inventory holding to reduce by £5 million, while the ability to order for next day delivery increased on-shelf availability, subsequently increasing sales. The shops now had more space and a wider range of titles, as well as flexibility to tailor their range to their local market.

Today, in-store and online, Waterstones handles in excess of 30 million books and 10 million related products per annum. The Unipart/Waterstones partnership swept the board at the 2015 European Supply Chain Excellence Awards, winning three awards as a result of the supply chain transformation work and a fourth for Unipart, who were awarded Best 3PL.

Select another article

Thinking that goes Beyond Logistics for Sky

How we have helped our customer, Sky build their competitive advantage in a fast changing world, by finding new ways of improving the service their customers receive.

Sky has built a strong position in the UK as a satellite television provider but as with so many markets it is being challenged by changes in technology and new entrants.

Retaining customers in such a highly competitive and fast changing market is never easy. A key component of customer satisfaction is the reliability of the equipment provided by their broadcast provider. So when Sky asked us to take on the additional responsibility for repairs, we saw an opportunity that would go far beyond simply repairing their Skyboxes more swiftly and efficiently.

We aspired to be much more than a basic repair supplier and saw an opportunity that was bigger than simply improving the quality and cost of the repairs process.

That opportunity was about reducing the long term need for this process by capturing the root causes of failure and relaying them back to the manufacturers.

As a world-first for set top box repair, we introduced an automated test programme with over 140 points being checked in a thirty minute period, complemented by Flying Probe technology to further diagnose faulty components on PCB Boards at high-speed.

The use of this cutting edge technology provided not only accurate and objective testing to ensure correct diagnosis and repair but, importantly, also generated extensive data for further analysis. This test data was utilised to link our repair teams directly with field engineers and Sky Manufacturing, so that they could learn from each other and implement continuous improvement.

The insights and knowledge thus gained provided important input into the future product development and manufacture of the Skybox, resulting in significantly improved reliability for Sky’s eleven million customers.

Select another article

Thinking that goes BeyondLogistics for London Underground

Unipart Rail were invited to collaborate with London Underground to create a ‘Model Line’ satellite depot

Unipart Rail were invited to collaborate with London Underground to create a ‘Model Line’ satellite depot, handling London Underground’s infrastructure materials.

Bob Martin, London Underground’s Track and Signalling Warehouse Manager said the challenge was: “to establish London Road, one of the key operational centres in the city, as a platform from which to deliver best operational practice within the industry.”

Unipart Rail Expert Practitioners brought their logistics skills and experience together with London Underground’s knowledge of the industry; their combined expertise identified five areas that required their attention:

- Better understanding of the quality and value of materials.

- Identification of materials and their fitness for purpose.

- Improvements in the storage and product layout of the depot.

- Stricter standards on issues affecting Health and Safety.

- Redesign of operational processes and controls.

The team created a carefully structured action programme, which brought together the latest thinking and operational practice to tackle each of the five problem areas.

The action programme included the introduction of a new inventory management system and the removal of any unwanted products. A new purpose-built racking system was installed and new ‘product flow’ procedures were bought in that identified and categorised products by usage rate.

The whole depot received a much needed ‘facelift’, to portray a clean and modern image.

The transformation was remarkable, and Unipart Rail and London Underground established the London Road depot as an industry benchmark in operational practice.

The new system provided London Underground with greater understanding of their ‘product flow’ procedures, and the practicality of the depot layout was dramatically improved.

London Underground is now planning to roll-out the use of this system into other depots.

Select another article

MetLase delivers fast and precise engineering solutions

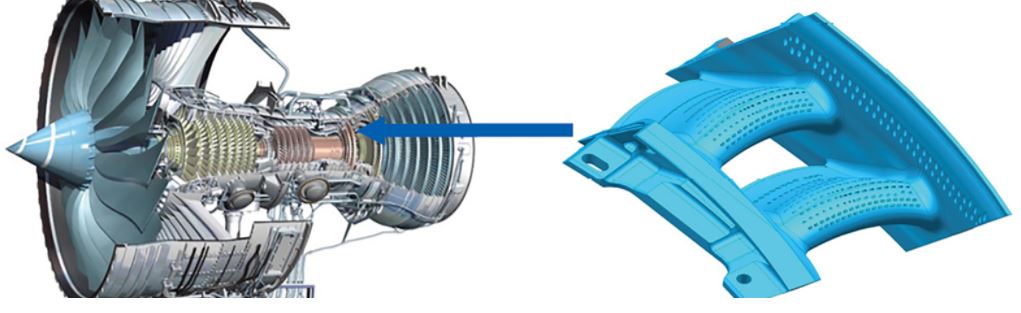

MetLase is a joint venture between Rolls-Royce and Unipart. It is a mechanical engineering consultancy whose technology-based approach and patented tooling techniques enables the design and manufacture bespoke engineering solutions with speed and precision.

This case study describes how MetLase created two full engine sets of turbine seal strips, at lead-times previously unobtainable.

Introduction

The turbine at the back of a jet-engine is a high-pressure, high temperature component which extracts power from the combusted gases. Gas must not flow past, so these engine components are precisely designed and have to be produced to within exacting tolerances.

MetLase was approached by the customer to create two engine sets of turbine seal strips within a very short time.

Solution

MetLase was able to employ its laminate press-brake tooling technology to quickly create the precise bend iterations required in the material, vastly reducing the usual lead time on these components.

Benefits

Two full engine sets were delivered within six hours of receiving the required geometry and specifications. This rapid delivery prevented an estimated 2 to 3-month slippage of the engine test programme and the associated costs incurred.

Summary

Adaptability: Quick turnaround of bend iterations through MetLase laminate press-brake tooling

Fast Make: 2 engine sets delivered within 6 hours of geometry receipt

Delivery: Rapid delivery prevented estimated 2-3 month slippage of engine test programme